Technological leadership quality priority. The products with User-friendly control and the control is easy to learn and operate.

Share:

PRODUCTS DETAILS

Zhejiang Nuojie Mixer Injection Molding Machine with a faster injection molding speed, our company’s Mixer Injection Molding Machine will satisfy the demands for high productivity.The Mixer Injection Molding Machinehigh speed injection characteristic.Technological leadership quality priority. The products with User-friendly control and the control is easy to learn and operate.

TECHNICAL PARAMETERS

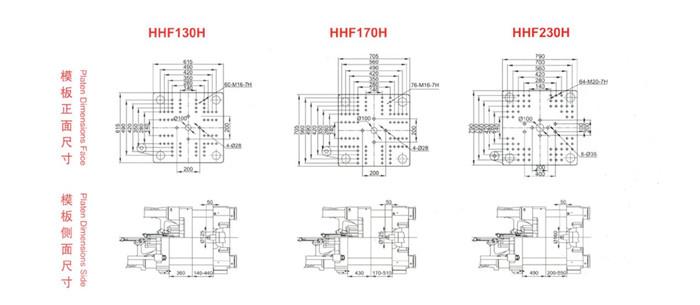

SPECIFICATION | HHF130H | HHF170H | HHF230H | |||

INJECTION UNIT | Primary Injection System | Secondary injection system | Primary Injection System | Secondary injection system | Primary Injection System | Secondary injection system |

Screw Diameter(MM) | 42 | 32 | 48 | 38 | 55 | 38 |

Screw L/D Ratio(L/D) | 21 | 21.8 | 21 | 21 | 21 | 21 |

Theoretical capacity(cm³) | 266 | 120 | 410 | 181 | 652 | 181 |

Injection Weight(G) | 242 | 109 | 373 | 165 | 593 | 165 |

Injection Rate(G/S) | 123 | 118 | 188 | 123 | 211 | 105 |

Injection Pressure(MPA) | 130 | 131 | 130 | 126 | 161 | 163 |

Screw Speed(RPM) | 150 | 150 | 160 | 150 | ||

CLAMPING UNIT | ||||||

Clamp Tonnage(KN) | 1300 | 1700 | 2300 | |||

Toggle Stroke(MM) | 360 | 430 | 490 | |||

Space Between Tie Bars(MM) | 415*415 | 470*470 | 532*532 | |||

Max.Mold Height(MM) | 440 | 510 | 550 | |||

Min.Mold Height(MM) | 140 | 170 | 200 | |||

Ejector Stroke(MM) | 120 | 140 | 140 | |||

Ejector Tonnage(KN) | 45 | 45 | 70 | |||

Number Of Ejector Rods(PC) | 5 | 5 | 9 | |||

OTHER | ||||||

Max.Pump Pressure(MPA) | 14 | 14 | 14 | |||

Pump Motor Power(KW) | 18.2+18.2 | 23+18.2 | 29+18.2 | |||

Hearter Power(KW) | 9.8+9.8 | 11+9.8 | 21.55+9.8 | |||

Machine Dimension(M) | 4.6*1.38*2.1 | 5.1*1.4*2.5 | 5.6*1.42*2.9 | |||

Machine Weight(T) | 6.2 | 7 | ||||

Oil Tank Capacity(L) | 240 | 300 | 500 | |||

PRODUCTS DISPLAY

Our Services

1,We will offer you detail manual books for our machines, also we will make one Video CD to show you how to install and maintain the machines, the CD is the movie for the machines, it will be the great references for you to maintain the machines for the long time.

2,Another way is that we can send our engineers to your factory to install the machines and train your engineers, we think it is the best way to help you operate and maintain the machines. We have been doing the install jobs for our overseas customers for many years. In this way you need to pay for the travel costs for our engineers, because our initial quotes don’t include the travel costs.