Temperature may be adjusted, silicone oil pressurized by purified air is injected to prevent blocking of spray gun, it is provided with vibration hopper or centrifugal hopper feed mode

Share:

PRODUCTS DETAILS

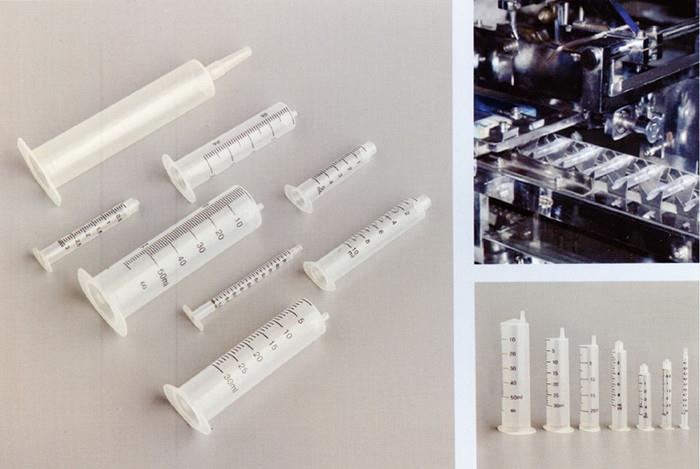

The Syringe Screen Printing Machine applicable for printing of 1ml- 60ml syringes, the printer adopt MITSUBISHI programmable controller (PLC), MITSUBISHI frequency converter, touch screen, photoelectric monitoring, automatic no-feed stop, electric heating tube for heating and drying .Temperature may be adjusted, silicone oil pressurized by purified air is injected to prevent blocking of spray gun, this Syringe Screen Printing Machine is provided with vibration hopper or centrifugal hopper feed mode

TECHNICAL PARAMETERS

Assembling Area | 1ml | 2ml | 5ml | 10ml | 20ml | 60ml |

Assembling speed | 100/min | 120/min | 120/min | 120/min | 110/min | 80/min |

Input | 220V50HZ | |||||

Machine Size | 250*180*220cm | |||||

Power | 2.5KW | |||||

Weight | 600KG | |||||

Air Pressure | 0.2-0.4MPa | |||||

PRODUCTS DISPLAY

FAQ

Q1: How about your after-sale service

A: We will response customer within 12 hours.

We will guide customer by video call.

If requset , we will send engineer to customer's factory to solve problem on site.

Q2: How long does the whole project take

A: From Initial design to final approval at customer site ,it takes 1 year.

6 month for design ,fabrication and test.

3 month for shipment and transport.

Another 3 month for on site installation ,trainning and trial run.

Q3: Can I get supplies and wearing parts from you?

A: Yes, we provide all the wearing parts for our printers always and they are in stock.