Fully automatic assembly machine for producing safety vaccine syringes, safety needle syringes, safety caps, and safety sheaths. The machine was professionally designed in China.

Share:

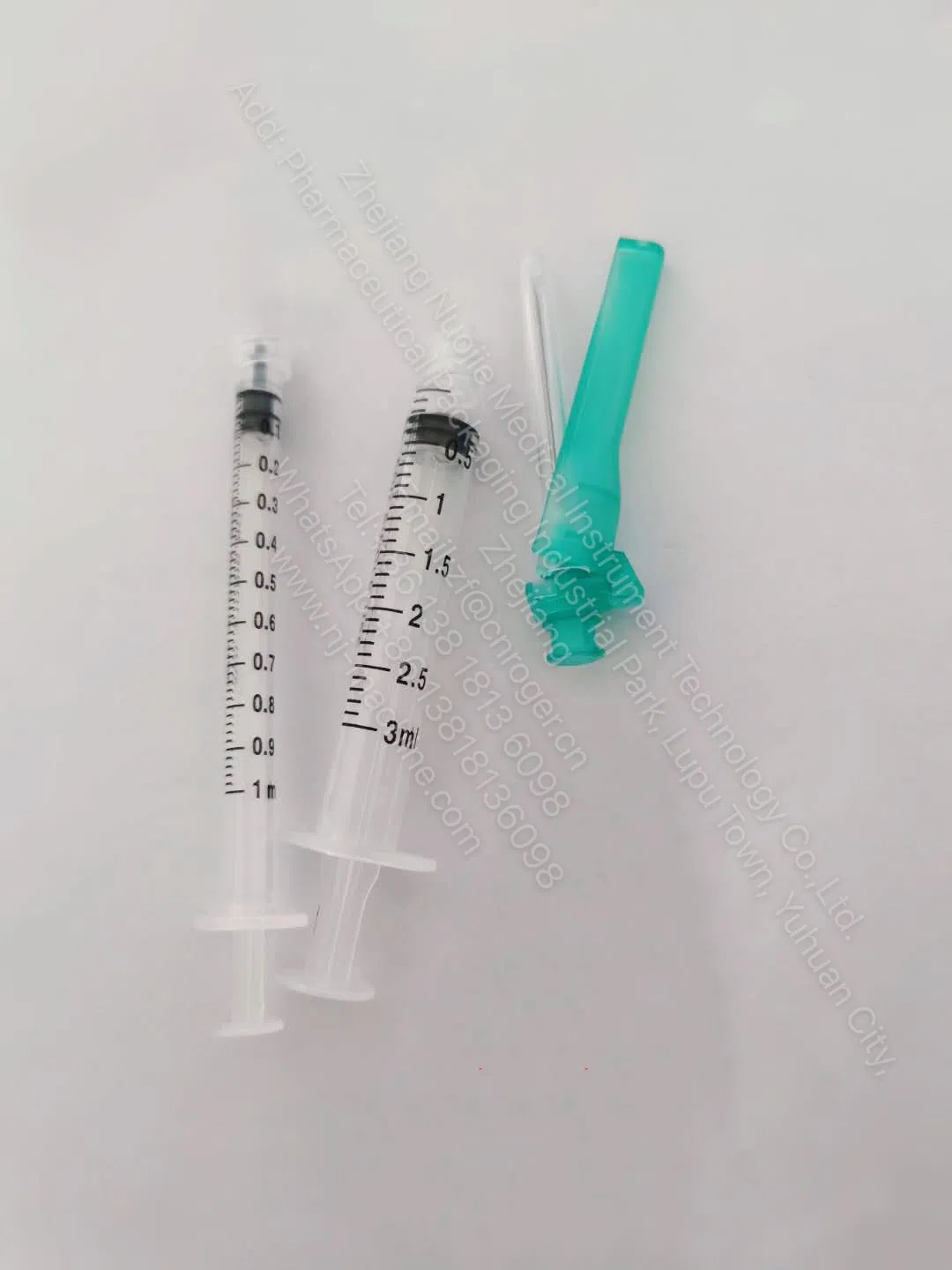

Safety Vaccine Syringe Products Details

This is a fully automatic assembly machine for producing safety needle syringes, safety syringes and vaccine syringes. The machine obtained a Chinese design patent. It is the latest third generation design of our factory. High productivity and stable production. The equipment adopts KEYENCE programming control system, and the panel adopts touch screen operation mode, which is simple and convenient. Servo motor gluing mechanism makes the gluing process smooth and even. The detection system adopts Japanese Keyence CCD image, and the pneumatic configuration adopts famous brand originals.

Safety Vaccine Syringe Technical Parameters

Output | 18,000 - 20,000 pcs per hour | ||||||

Gas consumption | 70 cubic per hour | ||||||

Whole machine power | 18KW | ||||||

Rate pressure | >0.6MPa | ||||||

Area covered | 12m*7m | ||||||

Equipment weight | About 6 tons | ||||||

Operators | 4-5 persons | ||||||

Safety Vaccine Syringe Products Display

Technological Process

Needle hub loading → needle hub pressing → needle cannula loading → needle hub gluing twirl the needle 1 → twirl the needle 2 → oven drying → jam detecting → needle burr detecting by CCD → silicification → unqualified product rejecting → Protective cap loading → cap pressing → finished product Discharging